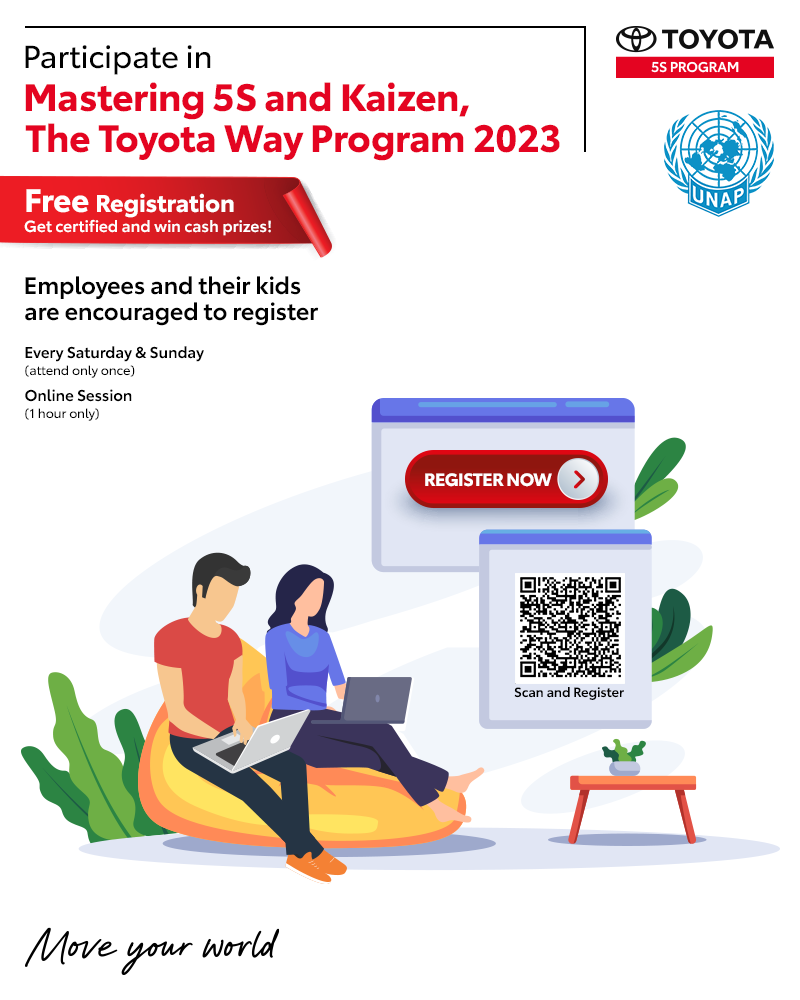

The Toyota Way Training 2024

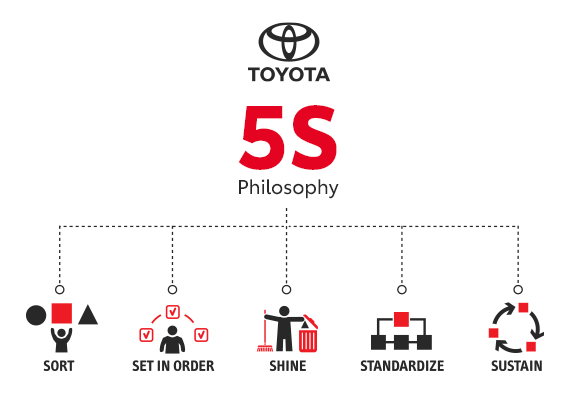

Welcome to the Toyota Way and 5S Training Program – a comprehensive initiative designed to introduce participants to the world-renowned methodologies of the Toyota production system and 5S methodology. This training offers a unique opportunity for individuals to delve into the principles of kaizen (continuous improvement), 5S (Sort, Set in order, Shine, Standardize, Sustain), and Toyota’s renowned philosophies, all while enhancing both their professional and personal lives.

Why Toyota Way and 5S Training?

The Toyota Way is more than just a set of manufacturing principles; it’s a philosophy that emphasizes continuous improvement, respect for people, and long-term thinking. Through this training, participants will gain valuable insights into how these principles can be applied not only in the workplace but also in their daily lives, leading to increased efficiency, productivity, and overall satisfaction.

Additionally, the 5S methodology provides a systematic approach to workplace organization and standardization, resulting in cleaner, safer, and more efficient work environments. By incorporating 5S practices into their routines, participants can streamline processes, reduce waste, and create a more conducive atmosphere for success.

Benefits of Participation

Participating in the Toyota Way and 5S Training Program offers numerous benefits:

Professional Development

Gain valuable knowledge and skills that are highly sought after in today's competitive job market.

Personal Growth

Apply kaizen principles to your personal life, fostering continuous improvement and personal development

Remote Accessibility

Access the training remotely from anywhere in the world, making it convenient for participants with busy schedules or limited access to traditional training programs.

Cost-Free

This training program is completely free of charge, ensuring accessibility to individuals from all walks of life.

Certification

Upon completion of the program, participants will receive a certificate recognizing their achievement, validating their understanding of Toyota Way and 5S methodologies.